Dexory

Founded Year

2015Stage

Incubator/Accelerator - II | AliveTotal Raised

$142.01MMosaic Score The Mosaic Score is an algorithm that measures the overall financial health and market potential of private companies.

+72 points in the past 30 days

About Dexory

Dexory specializes in robotics and artificial intelligence-driven logistics solutions within the technology domain. The company offers an integrated system that combines stock-scanning robots with a digital twin platform to provide real-time inventory and warehouse analytics. Its solutions are designed to serve various sectors, including logistics and supply chain, manufacturing, food and beverage, retail and electronic commerce, and cargo handling. Dexory was formerly known as BotsAndUs. It was founded in 2015 and is based in London, United Kingdom.

Loading...

Dexory's Product Videos

ESPs containing Dexory

The ESP matrix leverages data and analyst insight to identify and rank leading companies in a given technology landscape.

The warehouse scanning systems market provides warehouse operators with tech-enabled scanning solutions such as barcodes and RFID tagging to track inventory movement and location within warehouses. RFID solutions offer advantages like faster scanning and line-of-sight-free tracking but are more expensive than traditional barcode systems. These solutions integrate with warehouse management systems …

Dexory named as Challenger among 15 other companies, including Zebra Technologies, Siemens, and Honeywell.

Dexory's Products & Differentiators

DexoryView

Keeping track of inventory and making sure everything is where it should be is super important for running a smooth, organized warehouse. Before businesses dive into advanced strategies to make things faster or better, they have to make sure their inventory syste

Loading...

Research containing Dexory

Get data-driven expert analysis from the CB Insights Intelligence Unit.

CB Insights Intelligence Analysts have mentioned Dexory in 4 CB Insights research briefs, most recently on May 16, 2025.

May 16, 2025 report

Book of Scouting Reports: 2025’s AI 100

Apr 24, 2025 report

AI 100: The most promising artificial intelligence startups of 2025

Feb 13, 2025

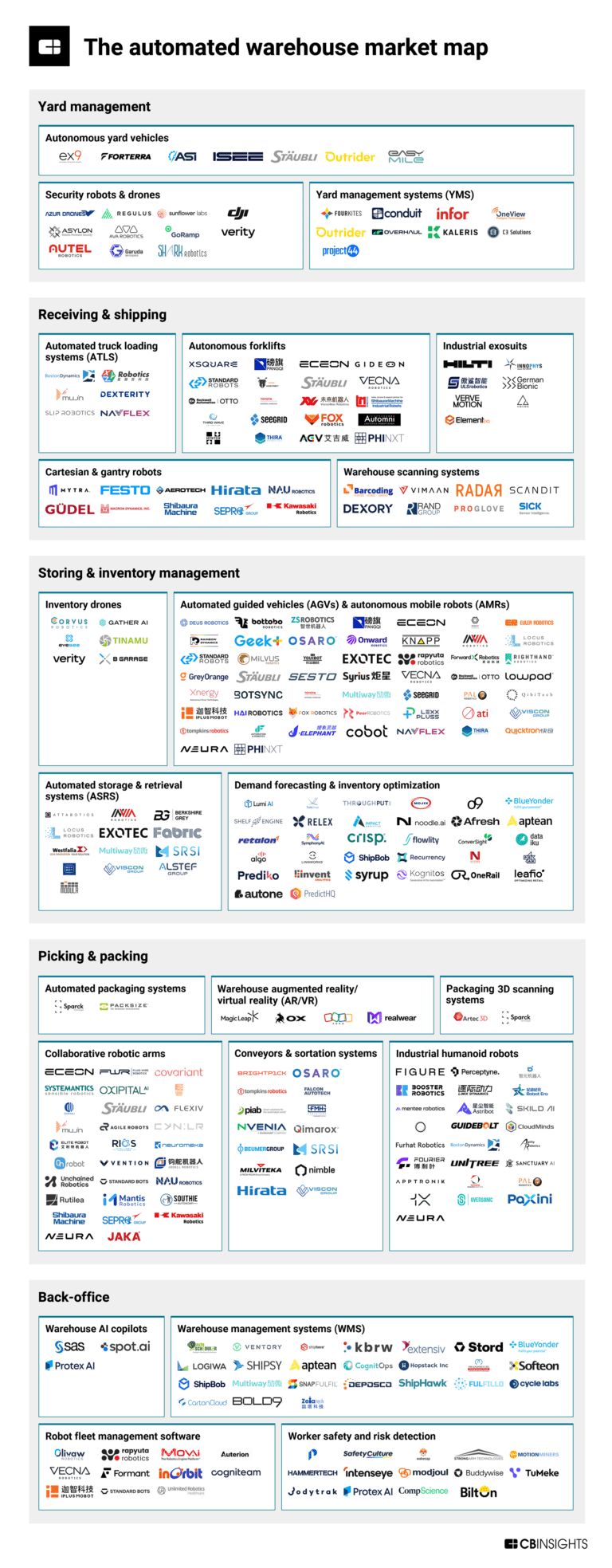

The automated warehouse market map

Dec 22, 2023

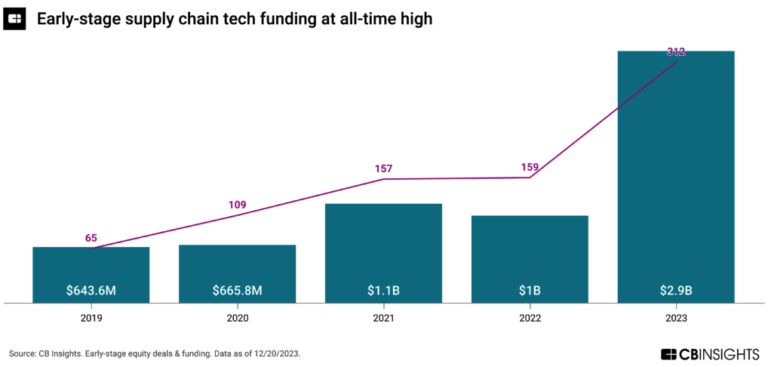

5 supply chain markets gaining momentum in 2024Expert Collections containing Dexory

Expert Collections are analyst-curated lists that highlight the companies you need to know in the most important technology spaces.

Dexory is included in 9 Expert Collections, including Store tech (In-store retail tech).

Store tech (In-store retail tech)

1,798 items

Companies that make tech solutions to enable brick-and-mortar retail store operations.

Supply Chain & Logistics Tech

5,262 items

Companies offering technology-driven solutions that serve the supply chain & logistics space (e.g. shipping, inventory mgmt, last mile, trucking).

Robotics

2,716 items

This collection includes startups developing autonomous ground robots, unmanned aerial vehicles, robotic arms, and underwater drones, among other robotic systems. This collection also includes companies developing operating systems and vision modules for robots.

Artificial Intelligence

12,998 items

Companies developing artificial intelligence solutions, including cross-industry applications, industry-specific products, and AI infrastructure solutions.

Sales & Customer Service Tech

752 items

Companies offering technology-driven solutions to enable, facilitate, and improve customer service across industries. This includes solutions pre-, during, and post-purchase of goods and services.

Advanced Manufacturing

6,887 items

Companies in the advanced manufacturing tech space, including companies focusing on technologies across R&D, mass production, or sustainability

Dexory Patents

Dexory has filed 1 patent.

The 3 most popular patent topics include:

- barcodes

- cartography

- encodings

Application Date | Grant Date | Title | Related Topics | Status |

|---|---|---|---|---|

11/23/2021 | Barcodes, Lidar, Encodings, Identifiers, Cartography | Application |

Application Date | 11/23/2021 |

|---|---|

Grant Date | |

Title | |

Related Topics | Barcodes, Lidar, Encodings, Identifiers, Cartography |

Status | Application |

Latest Dexory News

Aug 25, 2025

Aug. 25, 2025 Warehouses that prioritize visibility, smarter decision-making and flexibility will be in the best position to keep up. As supply chains continue to grow in complexity, the warehouse has emerged as both a challenge and an opportunity. Global disruptions, shifting customer demands and labor shortages have exposed the limits of traditional static operations, leaving organizations searching for new ways to create more intelligent and responsive environments. Companies like Amazon are increasingly turning to automation and robotics, with analysts at Morgan Stanley predicting that automation could save $10 billion annually by 2030. More companies are rethinking how their warehouses operate, especially in the face of ongoing change. Adaptive warehouses, designed to track what’s happening in real time and respond on the fly, are becoming a practical answer to that need. Adaptability is becoming a must-have in warehouse operations. By combining automation, AI and a steady stream of data, companies can cut down on errors, improve efficiency and make better decisions across the board. This article outlines the four steps—the blind, observable, intelligent and adaptive warehouse—in that journey and how each stage supports greater operational performance and supply chain resilience. 1. Understanding the Blind Warehouse Many traditional warehouses still operate with limited real-time visibility. Inventory is tracked using paper-based systems or spreadsheets, and stock counts are updated only during periodic audits. This leads to frequent errors such as misplaced items, stockouts and overstocking. With no automated data gathering or live insights, decisions are slow, reactive and prone to human error. While these warehouses benefit from lower upfront technology costs and minimal training requirements, they are increasingly vulnerable to inefficiencies, disruptions and lost revenue. As customer expectations rise, the drawbacks of manual, disconnected processes are becoming more costly than the technologies they seek to avoid. 2. Improving Visibility with the Observable Warehouse The first step toward modernization is visibility. In the observable warehouse, real-time tracking tools such as autonomous inventory systems, barcodes and warehouse management systems replace manual processes and provide more accurate views of stock and space. A study done by Auburn University’s RFID Lab found RFID tags, specifically, enable an increase in inventory accuracy from 63% to 95%. This is just one piece of the broader toolkit; with autonomous data-gathering systems, warehouses are able to reach a new level of visibility and data capture at scale. However, while data collection improves dramatically, insight generation and decision-making still rely on humans. These systems operate in silos, requiring teams to interpret data and take action manually. As a result, decision-making remains reactive, though more informed. 3. Driving Decisions with the Intelligent Warehouse In the intelligent warehouse, the introduction of artificial intelligence and machine learning transforms data into proactive insights. AI models forecast demand, flag anomalies and recommend resource allocation strategies, helping teams act faster and more accurately. This stage introduces basic automation of repetitive tasks like inventory tracking and slotting, freeing employees for higher-value activities. While human oversight is still required to validate insights and decisions, the process becomes far more agile and scalable. Forecasting errors are reduced, costs are better controlled, and warehouse operations become more responsive to market shifts. 4. Reaching Full Autonomy with the Adaptive Warehouse The adaptive warehouse represents the final stage: a self-optimizing environment where AI agents act autonomously to manage and improve operations in real time. These intelligent agents can assign tasks, adjust workflows and even reroute operations in response to disruptions, all without human intervention. For example, rather than allocating truck gates based on fixed rules, adaptive systems assess real-time conditions and dynamically assign slots to reduce dwell time. Inventory slotting strategies are updated automatically based on live demand and predicted patterns, and worker schedules can be adjusted in real time to meet changing needs. According to a report by McKinsey & Company , applying AI-driven forecasting to supply chain management can reduce errors by 20% to 50%, underscoring the potential for adaptive systems to significantly improve responsiveness and accuracy. This model not only boosts efficiency and accuracy, but also supports workforce transformation. As manual tasks are automated, employees shift into supervisory or innovation-focused roles. Additionally, adaptive systems contribute to sustainability by minimizing waste, energy use and resource consumption. Why Make the Move to an Adaptive Warehouse As warehousing demands continue to shift, the facilities that prioritize visibility, smarter decision-making and flexibility will be in the best position to keep up. Tools like real-time data and AI-driven automation are not just about keeping pace, they are becoming essential for staying competitive and meeting new standards for accuracy, speed and resilience. By making the switch to an adaptive warehouse, companies can transform the ways in which they operate and deliver value, ensuring they stay ahead in the dynamic warehouse automation market. Andrei Danescu is CEO and co-founder of Dexory , a provider of real-time warehouse visibility and automation solutions. About the Author Andrei Danescu | CEO Andrei Danescu is CEO and co-founder of Dexory , a provider of real-time warehouse visibility and automation solutions.

Dexory Frequently Asked Questions (FAQ)

When was Dexory founded?

Dexory was founded in 2015.

Where is Dexory's headquarters?

Dexory's headquarters is located at 242 Acklam Road, Portobello, London.

What is Dexory's latest funding round?

Dexory's latest funding round is Incubator/Accelerator - II.

How much did Dexory raise?

Dexory raised a total of $142.01M.

Who are the investors of Dexory?

Investors of Dexory include Tech Nation Future Fifty, SITL Innovation Awards, Capnamic, Kindred Capital, Maersk Growth and 15 more.

Who are Dexory's competitors?

Competitors of Dexory include Gather AI and 3 more.

What products does Dexory offer?

Dexory's products include DexoryView.

Loading...

Compare Dexory to Competitors

Verity specializes in autonomous indoor drone systems for inventory management within the logistics and warehousing sectors. The company offers a cloud-based inventory management system that utilizes self-flying drones to automate the scanning of inventory in large warehouses, aiming to achieve near-perfect inventory accuracy. Verity's solutions are designed to address labor shortages, enhance operational efficiency, and improve customer service by ensuring the right products are in the right place at the right time. It was founded in 2014 and is based in Zurich, Switzerland.

Corvus Robotics specializes in the development of autonomous drones for inventory management within the warehousing and logistics sectors. Its primary offerings include unmanned drones that autonomously navigate warehouses to scan pallet labels and provide inventory data, as well as software solutions that analyze and optimize warehouse inventory. Corvus Robotics' products are designed to serve industries such as third-party logistics (3PL), manufacturing, retail, and distribution, as well as accounting and consulting firms seeking efficiency in inventory management. It was founded in 2017 and is based in Boston, Massachusetts.

FlytBase develops enterprise drone autonomy software platforms within the drone technology industry. The company offers services that facilitate automated drone operations for various commercial applications such as security, inspections, and emergency response. Its solutions aim to work with existing enterprise systems, providing drone-in-a-box solutions that can be controlled remotely. FlytBase was formerly known as NavStik Labs. It was founded in 2013 and is based in San Jose, California.

Eyesee provides warehouse inventory management solutions for the logistics and manufacturing sectors. The company offers automated drones that scan barcodes and collect stock data within warehouses, which improves operational efficiency and data accuracy. Eyesee's drones operate within existing warehouse infrastructures, offering a solution for inventory processes without requiring additional fixed installations. It was founded in 2017 and is based in Grenoble, France.

Gather AI focuses on warehouse inventory management using drones and computer vision technology in the logistics industry. It provides data collection and insights for inventory intelligence, allowing visibility and control. It was formerly known as Nabla Ascent. It was founded in 2017 and is based in Pittsburgh, Pennsylvania.

D-Aria focuses on mobile data acquisition and automated inventory processing using drone technology in the logistics sector. The company provides a service that uses drones equipped with multiple sensors and vision-based technology to conduct inventory control and mission planning in warehouse environments. It is based in Vienna, Austria.

Loading...